LDM "Long-term Deployment Module” ( Antifouling )

- The newly patented anti-fouling module from HydroTech. (Patent number 7,437,248.)

- The most powerful anti-fouling (micro-fouling and macro-fouling) system in the market - "no gimmicks"

- No copper - no questionable chemicals

- Compatible with all existing multiprobes from all manufacturers

- Continuous deployment for one to three months in the worst conditions

- Guarantees stable and accurate measurements for all sensors

- Computer GUI will provide you with easy setup and maximum control flexibility

- Keeps sensors protected at all times during deployment

- SDI-12 ready

- Designed with all USGS needs in mind

- Can be used as an online underwater sampler with In-Situ measurement validated data

- With the LDM, you can now deploy a multiprobes in a discharge area where bubbling water would normally affect the sensors operation.

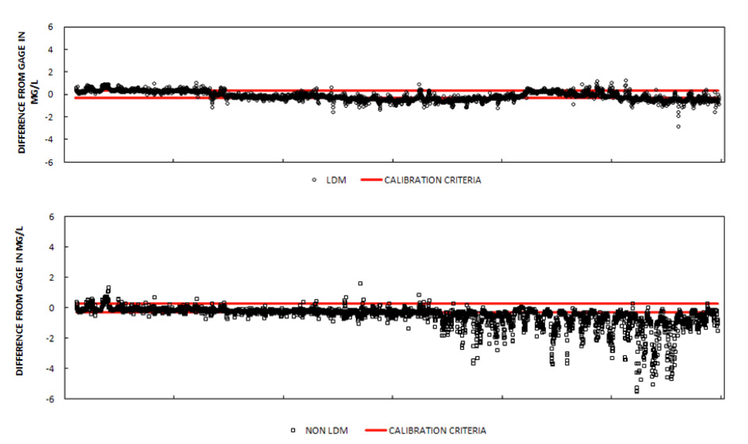

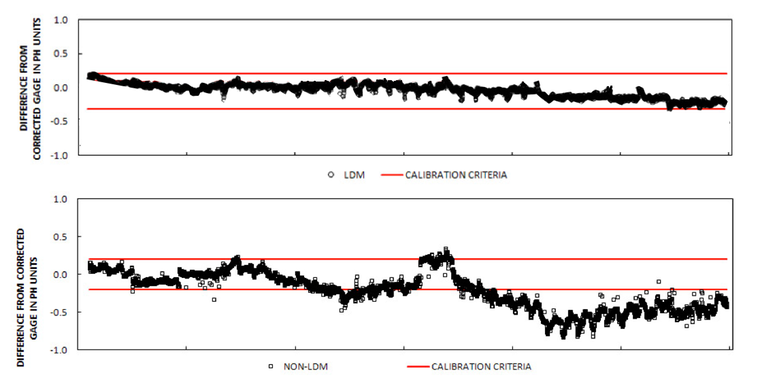

Here is what you should expect from the LDM: Two multiprobes were deployed side by side in an active water body for 6 weeks . One of them was equipped with the HydroTech LDM but not the other. See graphed data below.

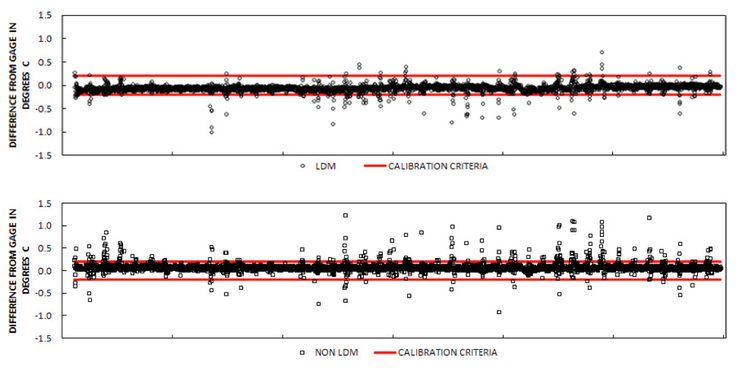

Optical DO: The LDM equipped multiprobe DO measurements are stable and accurate during the whole 6 weeks while the DO measurements from the other multiprobe without LDM are erratic and drift out of the calibration criteria just after 3 weeks.

pH : The LDM equipped multiprobe pH measurements are stable and accurate during the whole 6 weeks while the pH measurements from the other multiprobe without LDM are erratic and drift out of the calibration criteria just after 3 weeks

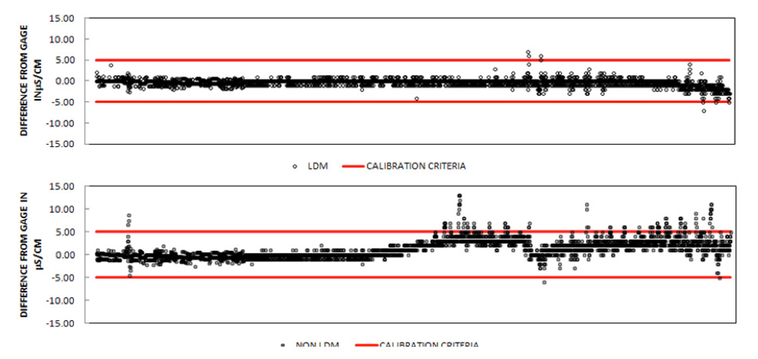

Conductivity: After 2.5 weeks of deployments fouling has already affected the conductivity measurements on the unit without LDM. While the LDM equipped multiprobe is still collecting stable and more accurate measurements.

Temperature: The LDM equipped multiprobe shows less sporadic temperature measurements. Sporadic temperature measurement affects data from all other sensors since they're temperature compensated.

A picture is worth a thousand words:

Sensor with and without LDM after 6-week deployment in a river

Sensors with and without LDM after 4-week deployment in the Corpus Christi Bay

Specs:

- Outer diameter: 4.5”/11.43 cm

- Length without guard: 14”/35.56 cm

- Weight: 7.4 lbs/3.35 kg (typical)

- Computer Interface: RS-232 and SDI-12

- Operating Temperature: 1 to 50° C

- Maximum Depth: 25 feet / 7.62 m

- Minimum water depth 2 feet

- Can be deployed to 20 degree angle from ground surface.

- Maximum water depth 25 feet ( 7.62 m )

Most common questions and answers:

Q: Can the LDM be used with any multiprobe?

A: Yes. The LDM is designed to work with any multiprobe from any manufacturer. The sample housing is multiprobe specific but it's field replaceable.

Q: Does the LDM require external power?

A: Yes. The LDM requires a 12 Volt external power source.

Q: Does the LDM operate with data-loggers like Sutron and Handar?

A: Yes. The LDM can communicate to any data logger that uses SDI-12 or RS232 communication protocols.

Q: Can the LDM operate in waters with high sediments ?

A: Yes. The LDM has an optional sediment filter at the intake. The end user can use any type of filter based on the application

Q: Can the LDM be deployed at an angle ?

A: Yes, the LDM can be deployed up to a 20 Degree angle from the ground surface.

Q: What is the maximum depth deployment for the LDM?

A: 25 feet under water ( 7.62 m )

Q: What is the minimum depth deployment for the LDM?

A: 1.65 feet under water ( 0.5 m )

Q: How does the LDM work?

A: The LDM has a valve, a pump, and a controller board inside. A measurement cycle has three phases:

Phase 1: Filling the sample housing. This is accomplished by opening a valve for a set duration inside the LDM. The hydrostatic pressure allows the water to flow via the intake through the valve then fill the sample housing.

Phase 2: Holding the water in the sample housing. The valve is closed and the water inside the sample housing is held for set duration.

Phase 3: Emptying the sample housing. The pump turns on and pumps the water from the sample housing through the side tube to the surface.

Q: What is the dual tube on the side of the LDM used for?

A: One tube is used to vent the sample housing to the surface which allows the sample housing to fill using hydrostatic pressure only. The other tube is used to evacuate the water from the sample housing to the surface for data validation at the surface if neede.

Q: What materials are used in the LDM ?

A:All housings are built with Grey PVC. The cable jacket is Polyurethane, the connectors are 3/16 stainless steel .

Q: Can the LDM be used in fresh and salt water?

A: The LDM can safely be used in fresh, salt water, and any body of water that is compatible with PVC, Polyurethane, and 3/16 stainless steel

Q: Are the LDM connectors waterproof?

A: The LDM under water connector is 100 % waterproof and designed to stay under water continuously. The DB9 surface connector is watertight only and cannot be submerged under water.

Q: Do you have any references for LDM users:

A: Yes. Please contact HydroTech for a list of customer references list. 512-846-2893 or email [email protected]

For a quote please email your request to sales or call 512-846-2893